The Japanese HySTRA pilot project demonstrates - as part of an international co-operation - a hydrogen supply chain between Australia and Japan consisting of the production, transport and use of CO2-free H2.

H2 is produced as blue H2 through the gasification of brown coal in Victoria, Australia, then purified and transported by lorry approx. 150 km to the port of Hastings. There, H2 is liquefied and transported by ship "Suiso Frontier" to Kobe, Japan, and unloaded at the "Hytouch Kobe" terminal built there for this purpose (the first terminal of its kind in the world). These deliveries were successfully launched at the end of 2021.

Work was also carried out as part of the HySTRA project to develop international safety standards for the production, transport, unloading and storage of liquefied H2. A comprehensive HSE strategy (Health, Safety, Security, Environment) was also developed.

One of the well-known project partners - alongside Shell Japan, Marubeni Corporation and Iwatani Corporation - was Kawasaki Heavy Industries (KHI). The benchmark-setting project was funded by NEDO (New Energy and Industrial Technology Development Organisation of the Japanese Ministry of Economy, Trade and Industry)

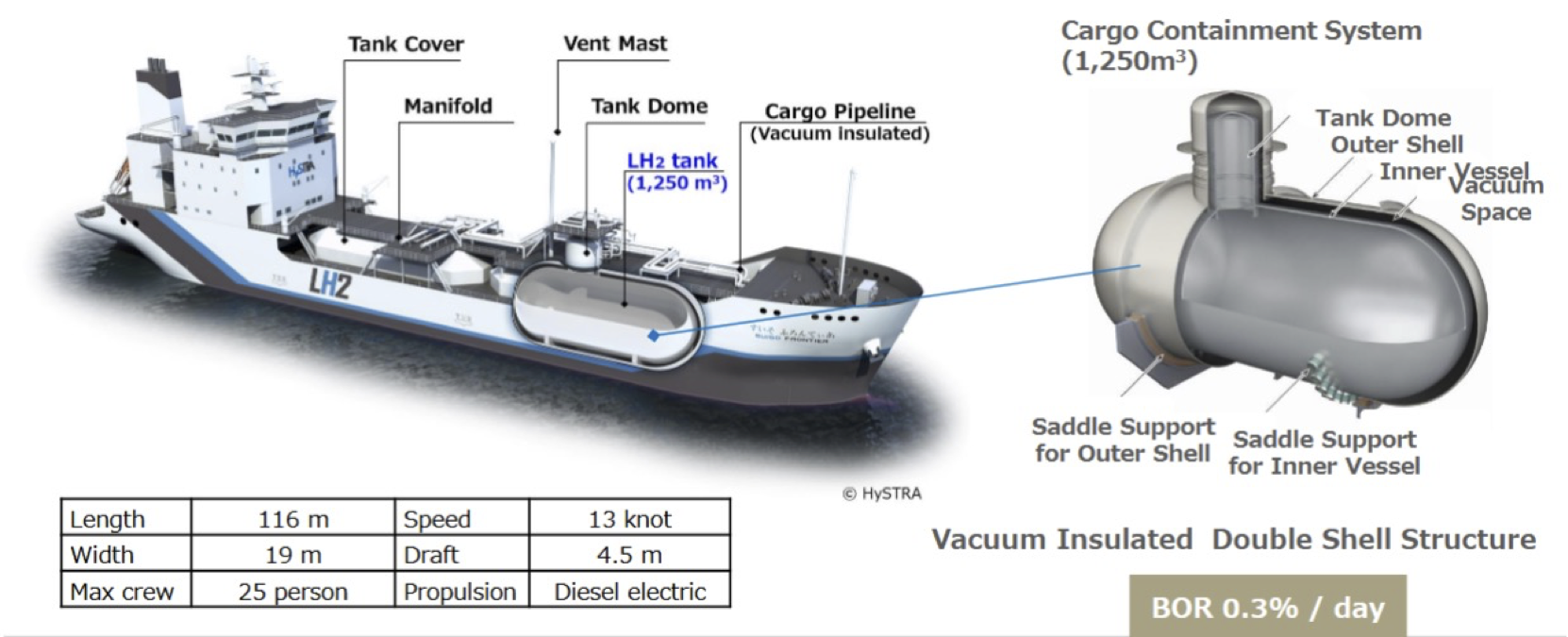

Kawasaki Heavy Industries developed the "Suiso Frontier" ship, demonstrating that large-scale and safe transport of liquefied hydrogen by sea is possible.

The ship is 116 metres long, 19 metres wide and can transport around 75 to 87.5 tonnes of liquefied hydrogen (H₂) per trip, stored in a 1,250 m³ vacuum-insulated double tank designed to minimise heat loss. The temperature rise over the 16-day, 9000 km journey from Hasting to Kobe is 1 Kelvin - with a required temperature of - 253°C to keep H2 liquid. The boil-off rate (BOR) is only 0.3% per day.

KHI has now published the decided further development of this ship. By 2030 at the latest - more likely 2029 - KHI will increase the possible transport weight - by accommodating 4 large H2 tanks - to 2400 tonnes per load, i.e. by a factor of approx. 27 - see the sketch below, taken from KHI

KHI is thus supplementing the previously favoured H2 transport methods using ammonia or methanol with the transport of liquid H2.

In an interview, we will try to find out why and under what conditions KHI decided to take this significant step. We will also try to find out more technical data - i.e. beyond the transport weight. This is particularly important in view of the fact that KHI is already considering the next but one expansion to 9,600 tonnes transport weight - see the sketch below.