A detailed look at the currently frequently mentioned topic of "hydrogen (H2) in power generation"

The use of hydrogen (H2) in power generation is discussed in many forums - but without mentioning costs or implementation hurdles. What does a rough analysis of these tasks look like? What adjustments need to be made?

The German power plant strategy assumes that natural gas-fired power plants with a total capacity of 12.5 GW - of which 10.5 GW are newly built - will be converted to H2 firing in the mid-1930s. In the exploratory talks between the CDU/CSU and the SPD, an additional 20 GW of natural gas-fired power plants are assumed, although the timing for a switch to H2 is/was not mentioned. The switch to H2 fuel requires

- Sufficient quantities of H2 available on the market at reasonable prices;

- the corresponding infrastructure such as pipelines, H2 storage facilities, etc.;

- mature H2 gas turbines - not only the necessary technology readiness level but also the corresponding commercial readiness level must be achieved.

For the development of H2 gas turbines, it should be noted that the flame temperature of H2 is approx. 400°C higher than the flame temperature of natural gas. The flame speed of H2 is approx. 7 times higher than the flame speed of natural gas. This means that the combustion chamber of the gas turbine must be designed differently and the materials must be adapted to the higher temperatures. This still requires a lot of research and development work, especially as the production costs of H2-fuelled gas turbines must be kept within reasonable limits.

If one assumes that the KW capacities specified in the German power plant strategy would actually be converted to H2 firing from 2035, the question of the marginal costs of the electrical energy generated by H2 gas turbines in 2035 arises.

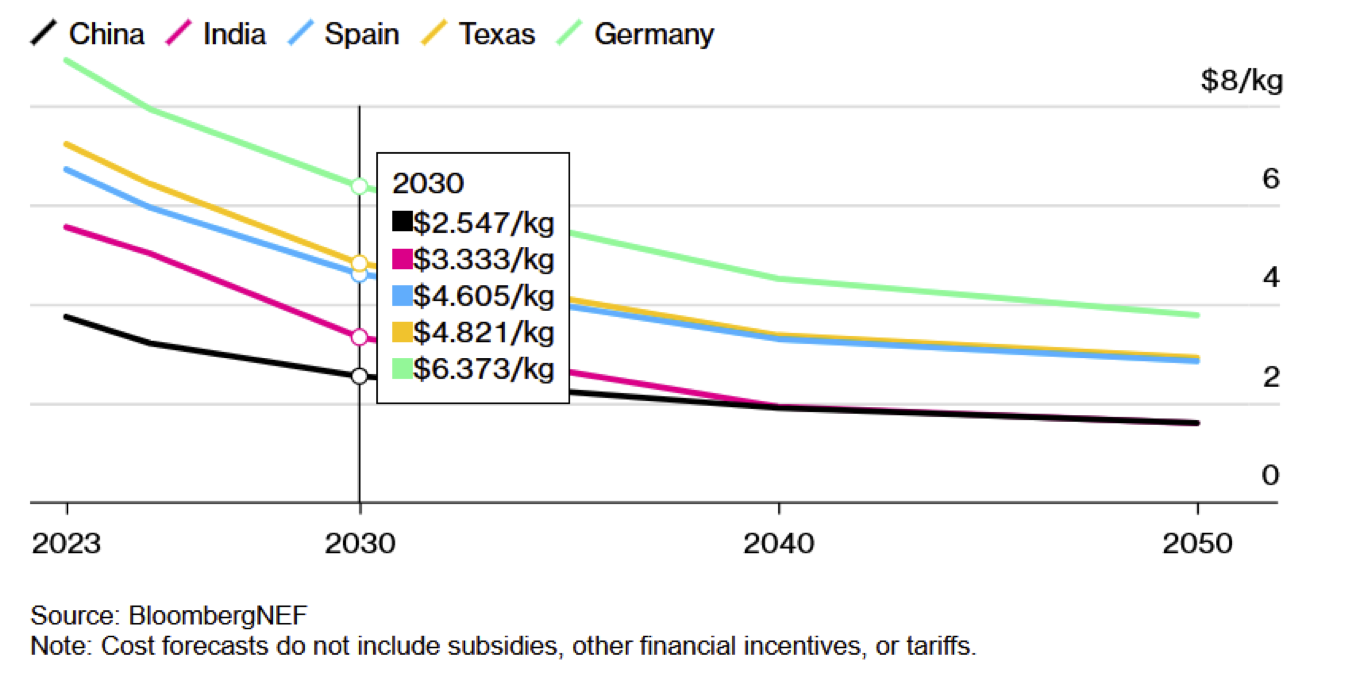

The forecast for H2 production costs is shown in the following chart - which has already been used in other articles on this information interface.

It can be seen that the production costs of H2 produced in Spain will be around €110/MWh in 2035 and around €140/MWh for H2 produced in Germany. (Note: the production costs of H2 produced in China are so low because China has so far mainly used alkaline electrolysers. This type of electrolyser can produce H2 considerably more cheaply but requires a constant production rate because fluctuations lead to gross H2 impurities and the alkaline electrolyser is relatively prone to errors due to production fluctuations). Assuming a total of approx. 30 - 40 €/MWh for H2 transport and H2 storage, the total costs for H2 are approx. 150 €/MWh (Spain) and approx. 180 €/MWh (Germany). Assuming an efficiency of 60%, fuel costs of approx. 250 €/MWh (H2 imported from Spain) and approx. 300 €/MWh (H2 produced in Germany) are incurred. Taking into account additional variable costs of approx. 50 €/MWh, this results in marginal costs of electricity generation of approx. 300 €/MWh if H2 is purchased from Spain and approx. 350 €/MWh if H2 produced in Germany is purchased. Depending on the tightness of the electricity market, the supply in the merit order list could be significantly higher - see prices during the dark doldrums last year.