There are various options for transporting pure hydrogen (H2), which has high production and storage costs, namely in liquefied form by ship or lorry, under pressure in cylinders or trailers by rail or lorry - or in pipelines. Pipelines are best suited for medium and long distances, as transport can be carried out efficiently, continuously and relatively cheaply. In order to gain a rough overview of the relevant transport criteria, these were described in the Hypa factsheet. In addition, some comments on the technical status quo and further prospects.

When talking about the energy density of the natural gas used in Austria, it should be specified whether we mean the calorific value or the heating value. The information in the Hypa factsheet regarding the volumetric energy density for H2, namely 10.78 MJ/Nm³ (3 kWh/Nm3), would indicate the calorific value of the same, but the figure of 35.5 MJ/Nm3 for natural gas does not correspond to the calorific value of the same - which would be 37.36 MJ/Nm3 (= 10.38 kWh/Nm3) - nor to the calorific value of 41.47 MJ/Nm3 (= 11.52 kWh/Nm3).

According to the above-mentioned factsheet, the pressure in natural gas pipelines and distribution lines is approx. 70 bar. Here it would be necessary to specify whether it is the gauge pressure or the absolute pressure - especially as approx. 70 bar suggests that the pressure can be around 70 bar - i.e. a little below but also a little above 70 bar. In fact, the pipelines mentioned in Austria are limited to a maximum operating pressure of 70 bar overpressure (pressure rating PN 70) - i.e. 70 bar overpressure is the maximum pressure and the safety valve opens immediately if this pressure is exceeded - even a little below.

The above-mentioned document states that approximately three times the power is required to compress the same amount of energy in the form of H2 at the same pressure stroke compared to natural gas compression. In fact, the power requirement increases by at least 3.5 times - more likely - depending on the compression ratio.

The factsheet also states that the use of centrifugal compressors for H2 requires approx. 3 times the number of revolutions compared to the compression of natural gas. The impeller material is cited as a limiting factor. This is only partially correct, especially as the centrifugal compressor is not used for transport in natural gas pipelines - i.e. large quantities at medium pressures - axial compressors are usually used for this purpose (note: axial and centrifugal compressors are summarised under the term turbo compressor).

The factsheet also claims that either piston or centrifugal compressors are used to compress H2 - in analogy to the application in the natural gas transport sector. In principle, axial compressors would be used for the pipeline transport of H2 - at medium pressures and compression ratios of approx. 1:2 - if they were available on the market. Axial compressors are used for natural gas transport in pipelines because they can handle very large flow rates at medium pressures, are often lighter and more cost-effective and also have good efficiency. Piston compressors are currently used for H2 transport in pipelines, even for medium pressures, because there are simply no axial or centrifugal compressors available on the market for compressing H2.

The use of turbo compressors for H2 compression is not readily possible from a fluidic point of view. If one compares the basic properties of natural gas and hydrogen, the differences in sound velocities are particularly striking in addition to the different densities. Compressing hydrogen with a turbocompressor is only possible if the sound velocity triangles at the impeller inlet and outlet remain the same (Mach's similarity). For pure hydrogen, therefore, a throughput approx. four times greater and a speed (circumferential speed) approx. four times higher would be required. This is almost impossible to realise for existing turbocompressor systems. For this reason, reciprocating compressors are currently used to increase the pressure of hydrogen.

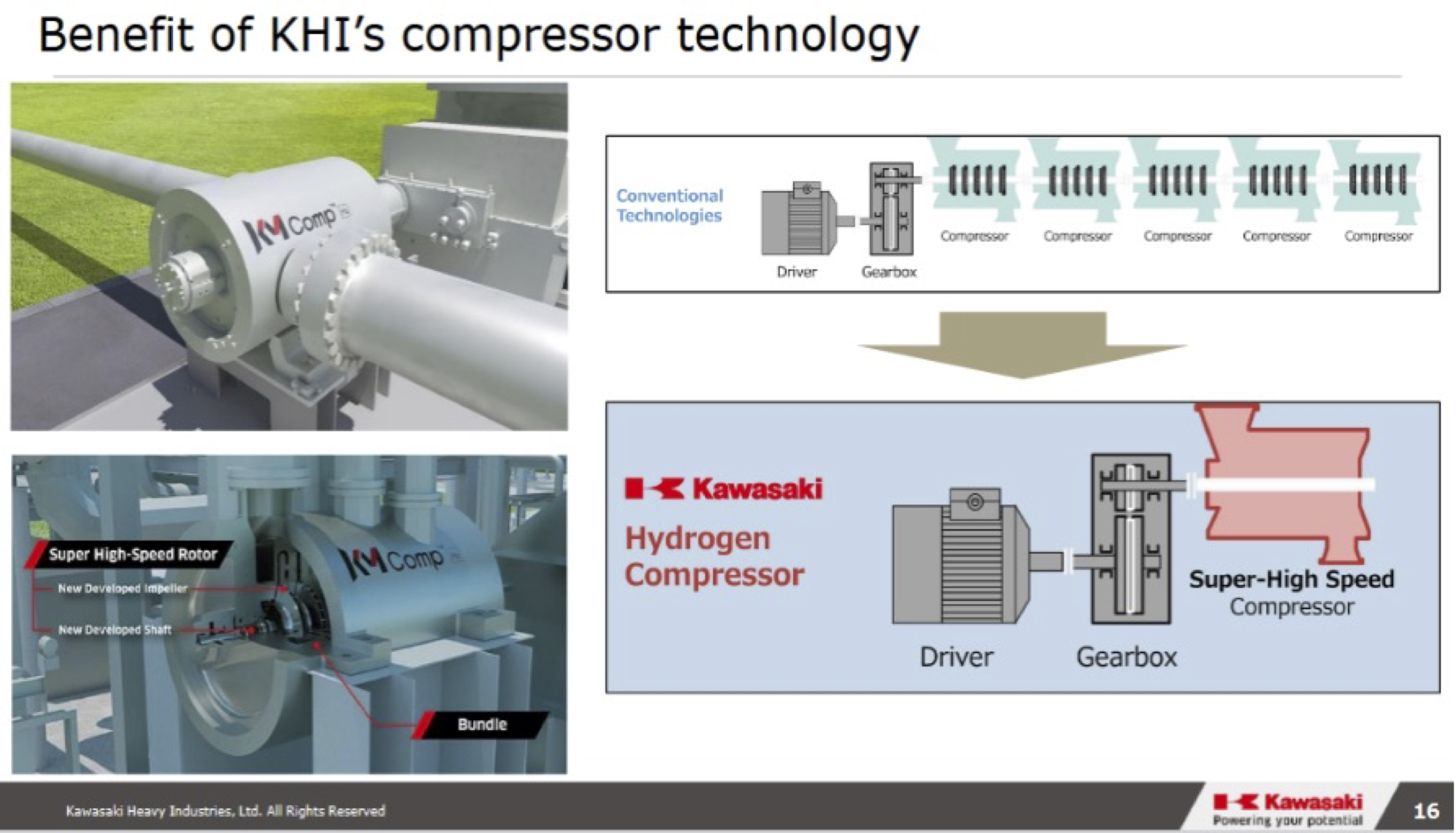

Recently, Kawasaki Heavy Industries presented an axial compressor for H2 compression. The pressure range and compression volume limits are not yet publicly known. The compression ratio must not exceed 1:2. This would be sufficient for the compression of H2 at pipeline level - however, the minimum operating pressure at pipeline level has not even been specified yet. How maximum transport capacities can be calculated in the absence of a permissible maximum pressure difference (maximum minus minimum operating pressure in the pipeline) remains a mystery.

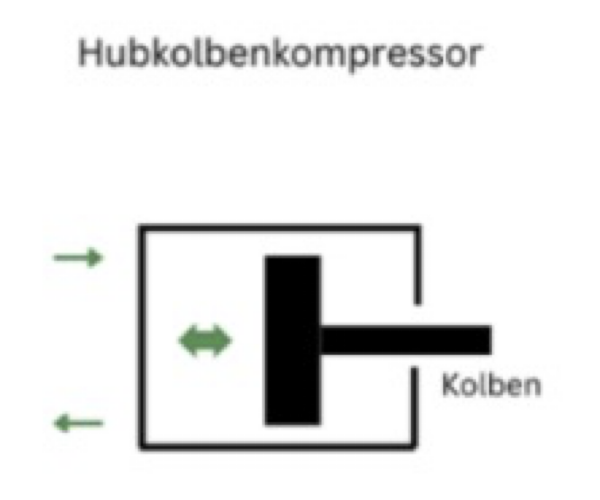

The Hypa factsheet provides a sketch of how a piston compressor works. A piston compressor does not usually work like an internal combustion engine (see sketch from Hypa factsheet p. 4) - with the exception of air compressors for domestic use - but compresses in both directions of piston movement, as shown in the diagram below.

With this design, the piston compressor is smaller and the pulsations (oscillating operation of the piston compressor), which pose a risk of material breakage and noise problems in the downstream pipework, are minimised. Nevertheless, a reciprocating compressor requires large pulsation dampers on both the suction and discharge side.

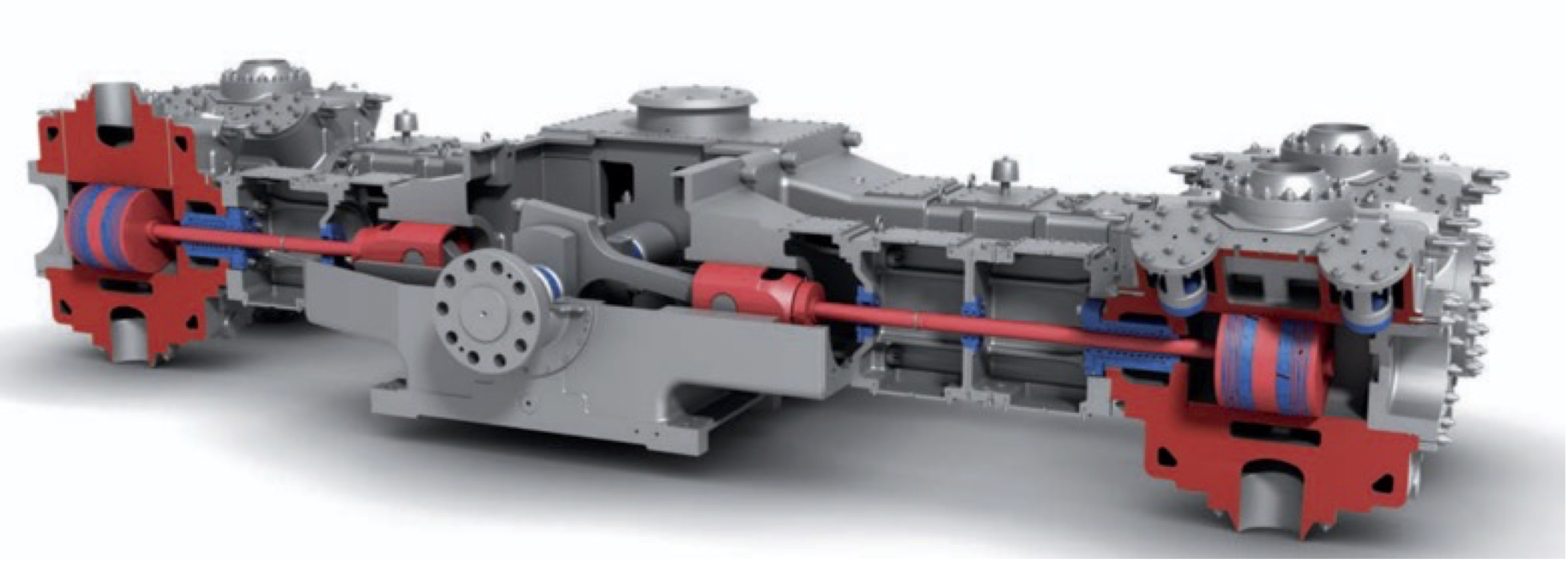

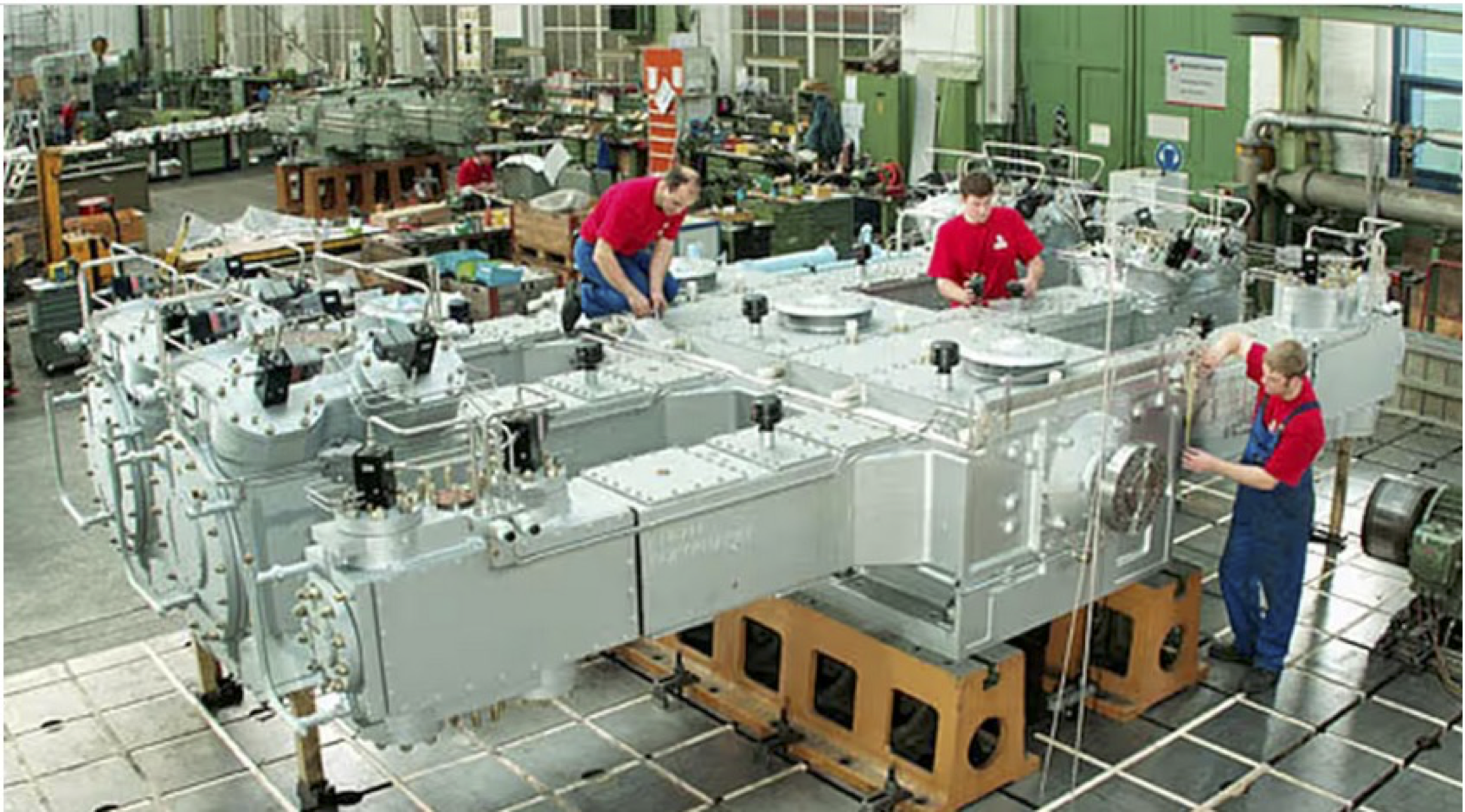

The factsheet claims that reciprocating compressors are used for compression volumes < 750,000 Nm3/h and centrifugal compressors for volumes above this. It is not clear where this figure comes from. At 750,000 Nm3/h H2, a compressor output of 25 MW would be required to compress 27 bara to 54 bara. That would be a monster of a reciprocating compressor - so this quantity would have to be divided up between many small reciprocating compressors connected in parallel anyway. If this arrangement is used, there is no upper volume limit - especially as, as already mentioned, there are currently no axial compressors (not even centrifugal compressors) available on the market for H2 compression - with the exception of the axial compressor recently launched on the market by Kawasaki Heavy Industries. To get an impression of the order of magnitude, a piston compressor from Burckhardt is shown below.

The axial compressor from Kawasaki Heavy Industries, on the other hand, has an almost cosy design - see the sketch below, taken from Kawasaki.

To avoid the bon mots mentioned in the Hypa factsheet, more careful research is required, otherwise factsheets can become fakesheets.